Optimum OPTIturn TX 4414 Manual Metalworking Lathe (3 Phase 400v)

£23,742.90 inc VAT £19,785.75 ex VAT

- Machine bed made of highly ribbed cast iron

- One-piece machine base made of steel

- High rigidity of the headstock housing due to highly ribbed 25GG cast iron

- Precision machined slides

- Shafts on needle bearings, All components are lubricated in an oil bath

- Bed guides hardened and precision-ground

- All electronic controls centrally accessible

- All gears of the feed gear are made of steel, hardened and ground

- Hand wheels decoupled and tested according to EN 23125

- Double channel right-left switch tested according to EN 23125

- Switch with life cycle calculation, tested according to EN ISO 13849

- Coolant unit with separate coolant tank with level indicator and oil separator; easy and complete emptying and cleaning according to DIN

- complete control system and feed spindle cover

- Complete illumination of the working area

- Service-friendly removable rear wall

- Hardened and ground face spindle guarantees enormous accuracy and durability

- Thanks to the high cutting performance, high chip removal during roughing machining is no problem

- Energy chain for gentle cable management and hose guide

- Lockable chip guard moves with the bed slide with integrated position indicator and coolant hose, manually movable

- No change gears necessary

- With safety device against simultaneous operation of threading and feed mechanism

- Electronically braked motor

- Electronically feed cut-off of Z-axis

- Electric position switch-off with quadruple position stop

- Three-jaw lathe chuck in standard scope of supply

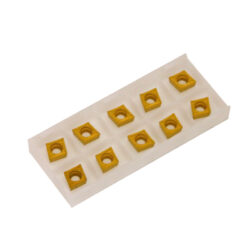

- Quick change steel holder SWH 5-B

- Digital position display DP700

DELIVERY CONTENTS

- Three-jaw lathe chuck Ø 200 mm No. 5

- Fixed centring tip MK 3

- Fixed centring tip MK 5

- Operating tool

- Machine initial filling with quality oil

- Quick change steel holder SWH 5-B

- Reducing sleeve MK 6 / MK 5

Description

0343-2420

Precision guide and drawbar turning machine

OPTIturn TX 4414

Meets highest requirements in technical equipment and precision. With digital NEWALL position indicator DP 700

Tech Data

|

Dimensions and weights

|

|||

| Length (product) approx. | 2300mm | Height (product) approx. | 1750mm |

| Width/depth (product) approx. | 1100mm | Net weight approx. | 1630kg |

| Work areas | |||

| Max. height | 220mm | Swing diameter above planing slide | 250mm |

| Max. width | 1280mm | Bed width | 300mm |

| Swing diameter above machine bed | 440mm | ||

| Speed range | |||

| Number of gears | 12stages | Speed range |

40 – 2200min¯¹

|

| Electric Data | |||

| Drive motor output | 5.5kW | Mains frequency | 50Hz |

| Supply voltage | 400V | ||

|

Cooling lubricant system

|

|||

| Cooling lubricant system coolant pump output | 100W | ||

| Spindle | |||

| Spindle chuck | Camlock DIN ISO 702-2 No. 6 | Spindle cone | MT 6 |

| Spindle bore/rod passage diameter | 52mm | Tool holder | SWH 5-B |

| Tailstock | |||

| Tailstock chuck | MT 4 | Tailstock quill diameter | 58mm |

| Tailstock quill stroke | 180mm | ||

| Pitches | |||

| Metric pitch | 0.5 7.5mm/rev | Diametrical pitch |

0.25 – 3.75mm x ?

|

| Imperial pitch | 60 4Gg/Zoll | Modular thread pitch | 120 8Gg/? |

| Travel | |||

| Travel X axis | 153mm | Travel Z axis | 290mm |

| Feed | |||

| Longitudinal feed range | 0.05 0.752mm/rev | Flat feed range |

0.025 0.376mm/rev

|

|

Electrical connections

|

|||

| Total rated value | 6.1kW |

Additional information

| Weight | 1500 kg |

|---|---|

| Brand | OPTIturn |

Reviews

There are no reviews yet.