Optimum OPTImill MH 20VL Drilling Milling Machine (230V)

£2,274.40 inc VAT £1,895.33 ex VAT

Features:

- Precisely built

- High concentricity due to tapered roller bearings 0.015 mm measured in the quill

- Motor with two-stage gear ratio for powerful transmission of motor power

- Manual quill feed with fine feed

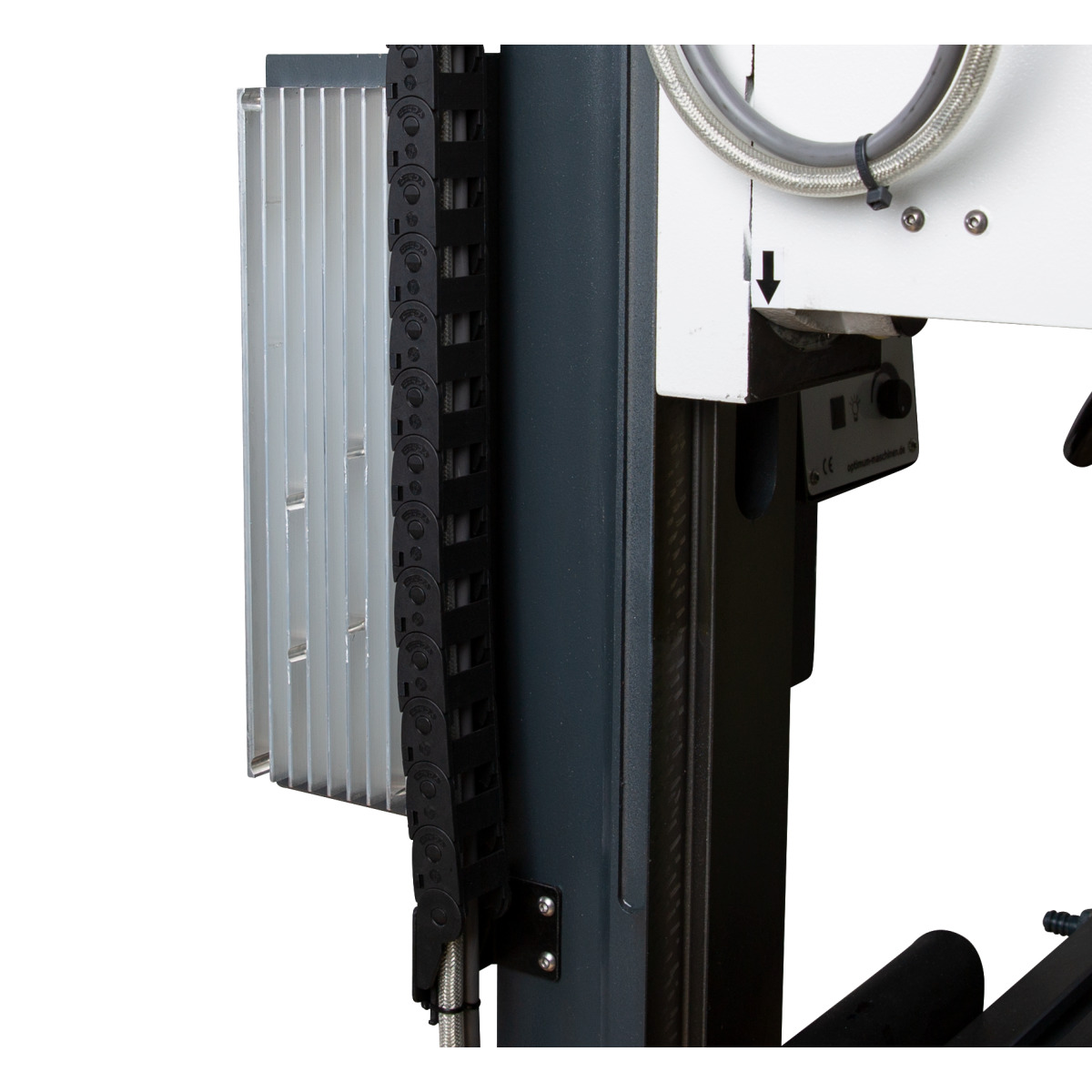

- Control electronics with integrated relay control

- Easy-to-read digital display for speed and drilling depth

- Stable dovetail guide with adjustable wedge strips

- The drilling and milling head can be tilted by ± 60°

- Fine milling feed

- Forward/reverse rotation

Description

0333-8132

Optimum OPTImill MH 20VL Drilling Milling Machine (230V)

- Precisely built

- High concentricity due to tapered roller bearings 0.015 mm measured in the quill

- Motor with two-stage gear ratio for powerful transmission of motor power

- Manual quill feed with fine feed

- Powerful DC motor with permanent current monitoring

- Safety electronics in 24 Volt version

- Control electronics with integrated relay control

- Clear control panel with user-friendly membrane keyboard

- Easy-to-read digital display for speed and drilling depth

- Solid and large dimensioned cross table, precisely finished with T-slots and adjustable wedge strips

- Adjustable end stops

- Stable dovetail guide with adjustable wedge strips

- Emergency stop impact switch

- The drilling and milling head can be tilted by ± 60°

- Fine milling feed

- Forward/reverse rotation

- Machine lamp

- Double-row angular contact ball bearings in the axes, adjustable without play

- Height-adjustable protective screen with microswitch, against flying chips and parts, for the greatest possible protection of the user

- X, Y and Z axes with prepared groove for the subsequent assembly of magnetic tapes

Optional Accessories

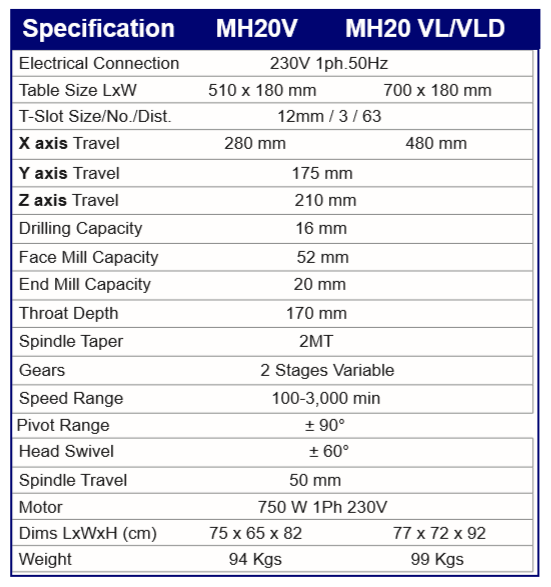

Technical Data

| Category | Dimension/Weight | Value |

|---|---|---|

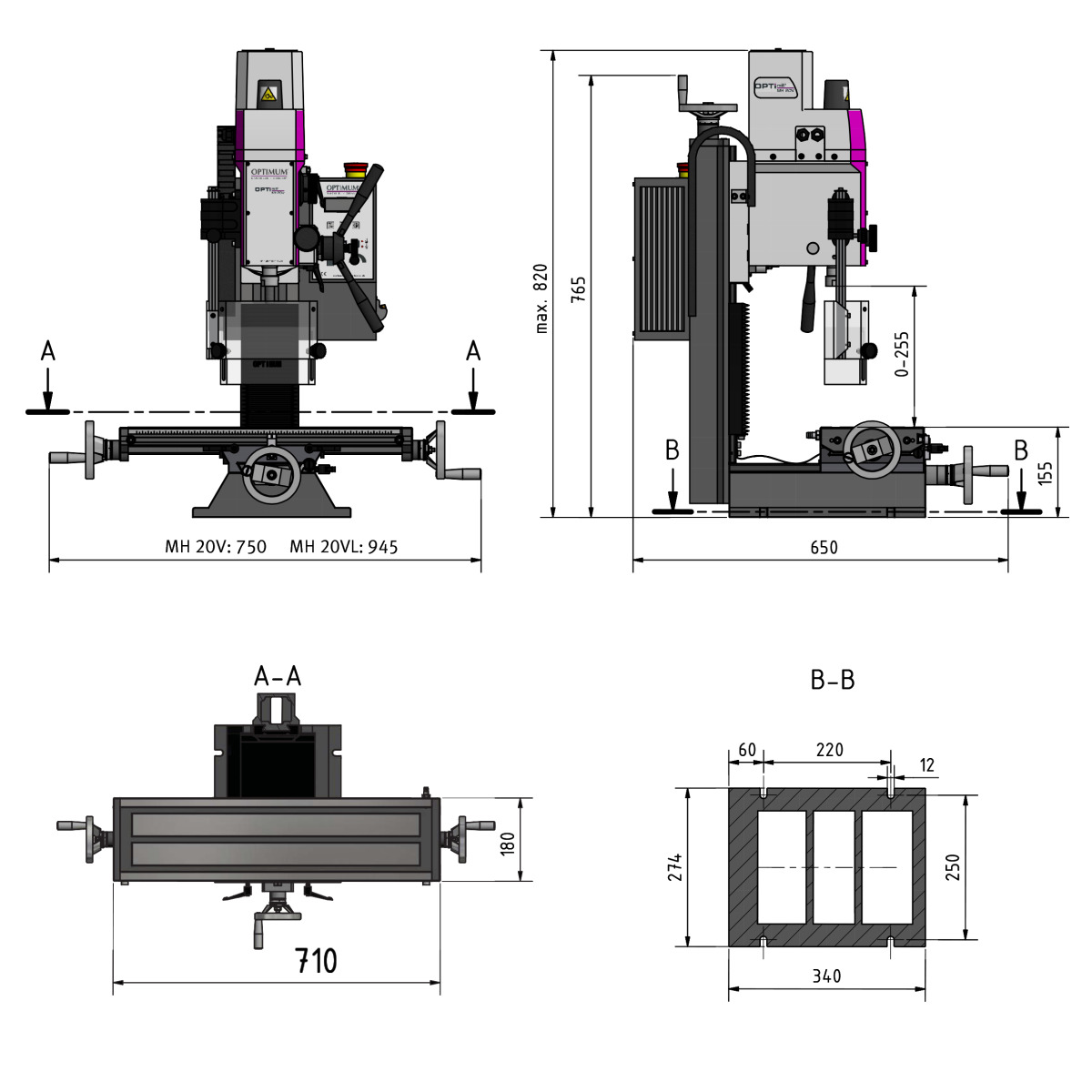

| Length (product) approx. | 770mm | |

| Height (product) approx. | 917mm | |

| Width/depth (product) approx. | 714mm | |

| Net weight approx. | 99kg | |

| Drilling/milling output | Drilling performance steel (S235JR) | 16mm |

| Max. size shaft milling cutter | 20mm | |

| Max. size milling head | 52mm | |

| Continuous drilling performance steel (S235JR) | 12mm | |

| Electric Data | Supply voltage | 230V |

| Mains frequency | 50Hz | |

| Milling table horizontal | Horizontal milling table length | 700mm |

| Horizontal milling table T-groove size | 12mm | |

| Horizontal milling table width | 180mm | |

| Horizontal milling table T-groove number | 3 | |

| Min. clearance vertical spindle – horizontal milling table | 255mm | |

| Horizontal milling table T-groove spacing | 63mm | |

| Max. clearance vertical spindle – horizontal milling table | 255mm | |

| Horizontal milling table max. load bearing capacity | 50kg | |

| Standards and certifications | Standard | DIN EN 55011 |

| EMC level | C1 | |

| Travel | Travel X axis manual | 480mm |

| Travel Z axis manual | 210mm | |

| Travel Y axis manual | 175mm | |

| Vertical spindle | Vertical spindle reach | 170mm |

| Vertical spindle quill diameter | 60mm | |

| Vertical spindle spindle chuck | MT 2 | |

| Vertical spindle quill stroke | 50mm | |

| Vertical spindle swivel range milling cutter head Z – X plane | 60° | |

| Vertical spindle speed control | electronically adjustable | |

| Vertical spindle speed range | 100 – 3000min¯¹ | |

| Vertical spindle drive motor output S6-30 % operation | 0.75kW | |

| Vertical spindle number of gears | 2 |

Additional information

| Weight | 99 kg |

|---|---|

| Brand | OPTImill |

Reviews

There are no reviews yet.