Optimum TH 4010D Mechanics lathe 3402080

£17,063.38 inc VAT £14,219.48 ex VAT

Fully equipped mechanic lathes. Convincing in precision and performance. TH 4010D with digital position indicator DPA 21, TH 4010V additionally with Siemens inverter vario drive

Description

Optimum TH 4010D

- Hardened and ground Z-axis guideway

- Spindle mount Camlock DIN ISO 702-2 No. 5

- Precisely crafted sled

- Handwheels with adjustable fine scale 0.04 / 0.02 mm

- Quadruple tool holder

- All guides can be adjusted by wedge strips

- Adjustment range upper slide ± 90 °

- Guaranteed concentricity of the spindle nose better than 0.015 mm

- Main spindle running in oil bath

- Gear wheels smooth, hardened and ground

- Gears and shafts hardened and ground, running in an oil bath in precision bearings

- Handwheels decoupled and tested according to EN 23125

- Two-channel right-left switch tested to EN 23125

- Switch with life cycle calculation, tested according to EN ISO 13849

- DC 24 Volt – electrics

- Lockable main switch

- Right / left rotation on bed sled switchable

- Safety handwheels with release function in the X and Z axis

- Tailstock for taper turning ± 10 mm adjustable

- Tailstock quill and hand wheel with adjustable fine scale 0.025 mm

- Fast, easy and tool-free adjustment by means of a clamping lever

- Strongly ribbed prism bed, induction hardened and precision ground from gray cast iron

- Extractable chip tray with guide rails

- Emergency stop device with foot control

- Machine base with 3 panels (no compartments)

- Coolant system

- LED machine lamp in chip protection

TH 4010 / TH 4010D:

- Motor protection switch

TH 4010D / TH 4010V:

- User-friendly membrane keypad, splash-proof, closed and glare-free

- Glass scales

Delivery Content:

- Fixed bezel passage Ø 5 – 85 mm

- Running bezel passage Ø 5 – 65 mm

- LED machine light

- Reduction sleeve MK 6 / MK 3

- Fixed centering points MK 3

- Fixed centering point MK 3, alloyed

- Change gear set

- Initial machine filling with quality oil

- operating tool

TH 4010 / TH 4010D

- Quadruple steel holder 16 mm

TH 4010V

- Quick-change steel holder 3-E

- Steel holder 20 x 100 type D for square chisels

Do not forget the lathe chuck!

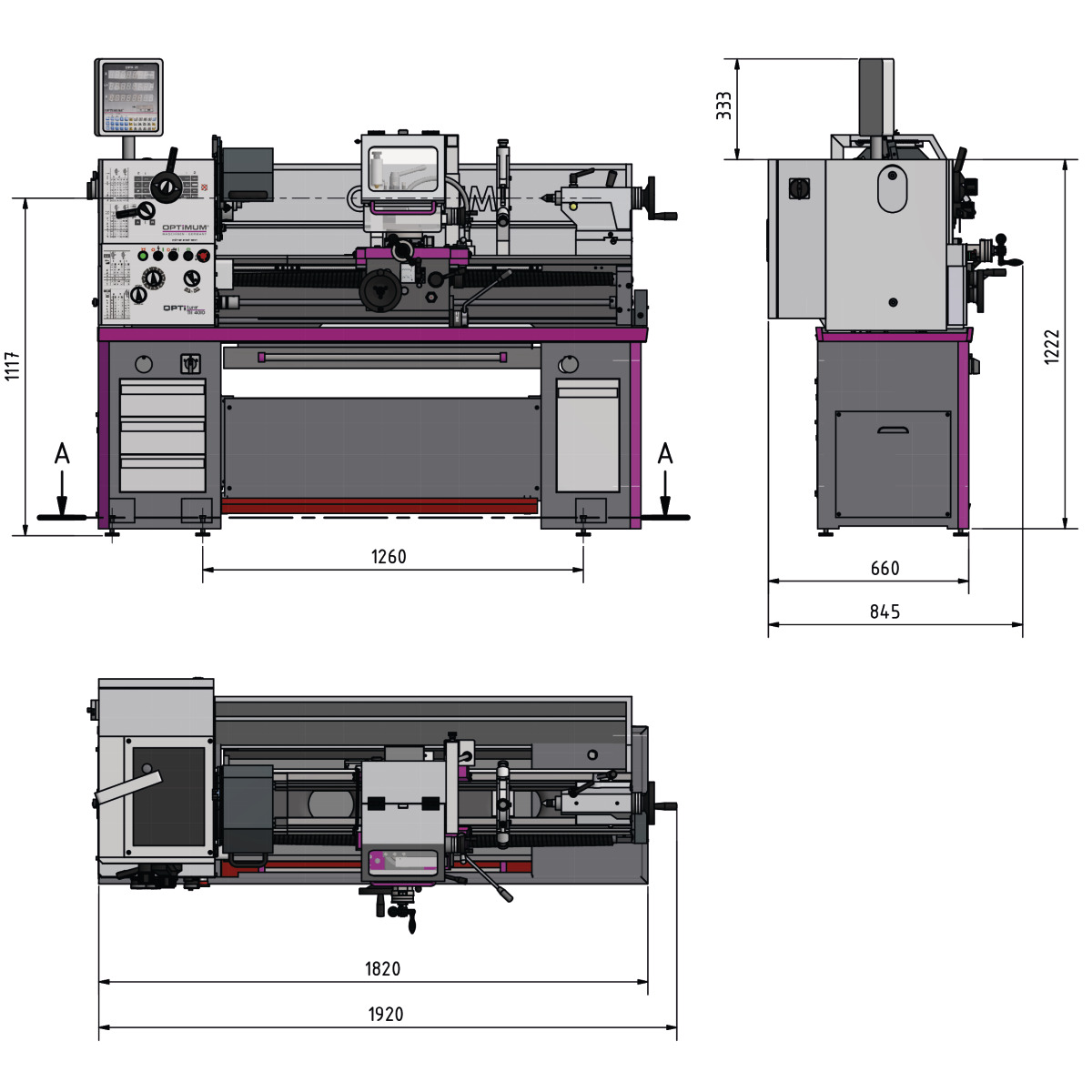

Dimensions(mm):

L: 1930 H: 1700 W: 920

Weight: 830kg