Baileigh PH-28HD Power Hammer 2038679

£25,103.20 inc VAT £20,919.33 ex VAT

- 2mm mild steel capacity

- 3.6mm aluminium capacity

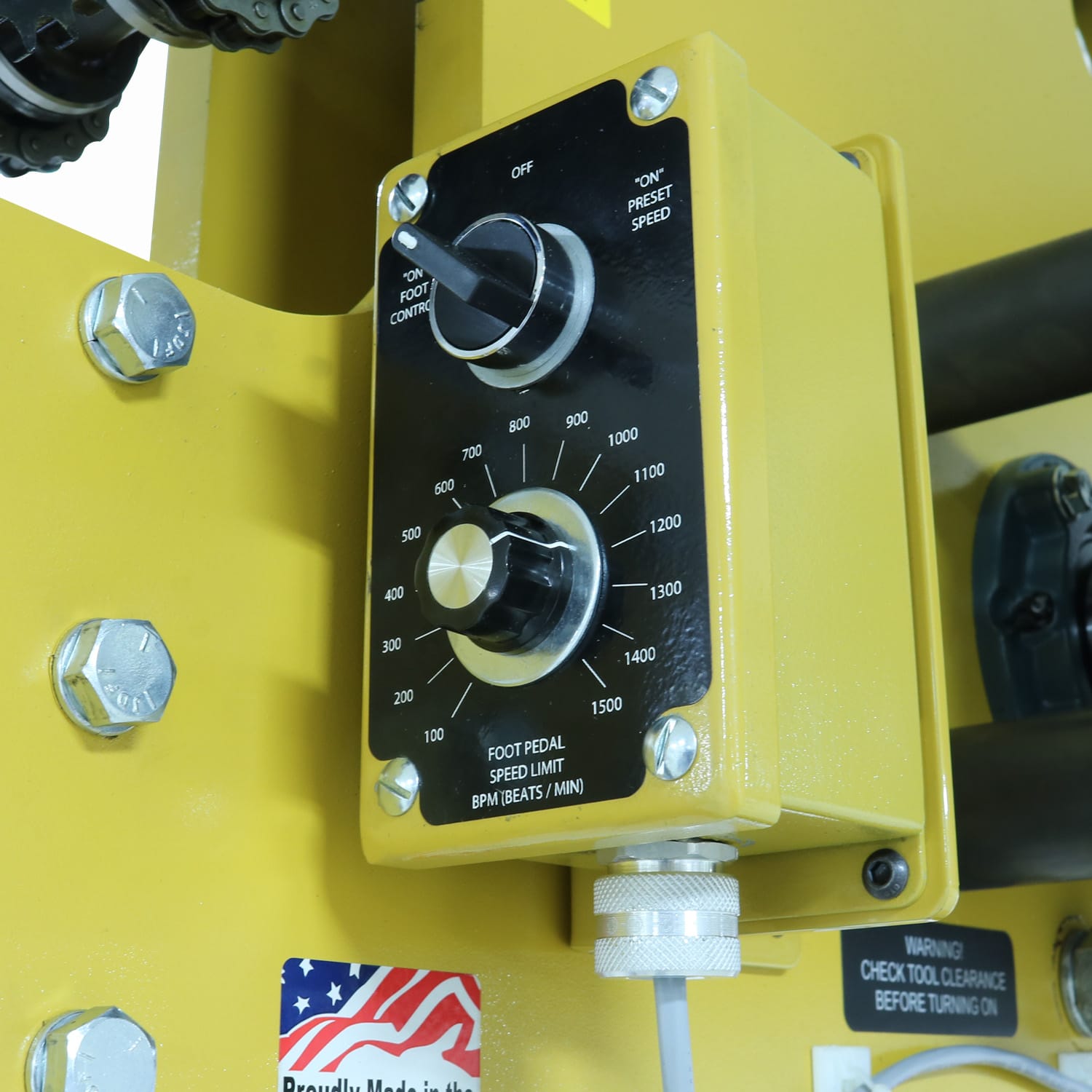

- 1000 beats per minute

- 711mm throat depth

Description

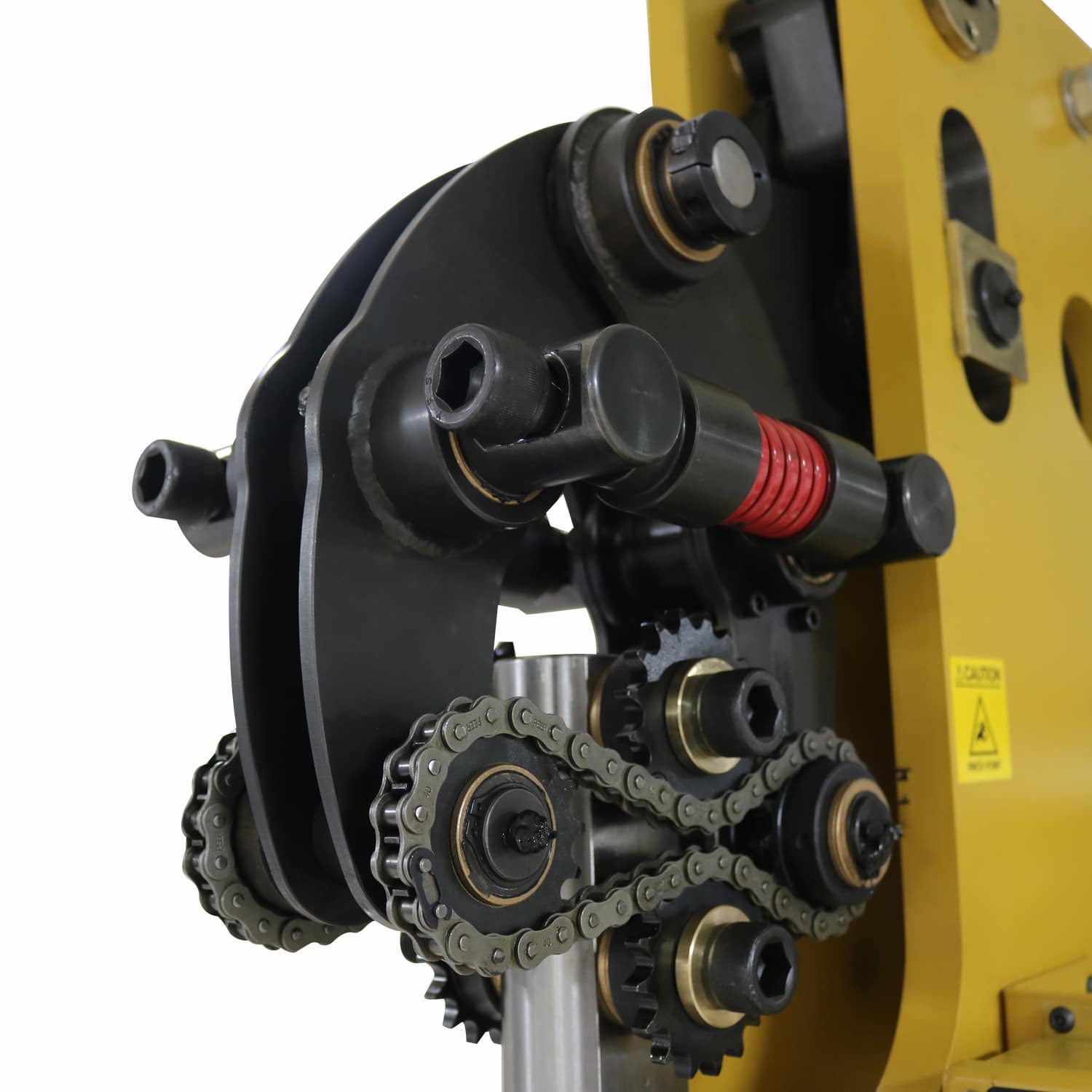

The PH-28HD Power Hammer was designed right here in Wisconsin to do one thing, and one thing only. hit .and hit hard. With a hit up to 75% harder than its predecessor, the MH-19 Power Hammer, this beast will move metal faster than just about any hammer its size. Extremely affordable and American Made, deep panel shrinking, stretching and planishing is now obtainable to nearly everyone in the market!The PH-28 was developed after over 20years of working with power hammers and determining what is most important to the metalshaper. After 10 years of sucessful applications of the MH19, we decided to scale back the functionality of the MH19 and create a Brand New hammer with several important key features in mind. 1) It needed to hit hard to shape the heavier gauges of steel by incorporating the Dupont linkage we used on the MH-37HD. By scaling it back, we came up with a very simple yet proven mechanism to utilize common, off the shelf die springs. Our unique floating chain / sprocket setup eliminated the leather strap commonly used on legacy hammers.2) The speed needed to be variable just like the MH-19 and MH-37, so the same electronics are used with a 3hp, 220v single phase motor.3) The tooling needed to be quick and easy to change, so we decided to use the same mounting system as the MH-19. We also incorporated a toggle lifting device that raises the to ram to separate the heads for tool changes, very quick and no hand tools are needed 4) The lower ram is fully adjustable up or down via a large acme thread, so if different tool thicknesses are required, you wont need to shim.5) The work height was raised from the MH-19 to allow better visibility of the “hit” mark.6) We also made the stroke adjustable between 3 fixed stroke settings: ¼, ½, ¾, these are easily selectable by removing and inserting a pivot pin into the corresponding stroke hole. For this setting you will need a 1″ socket and can be changed in about a minute. 7) Throat depth was increased to fit the larger panels from 19″ deep to 28″ deep.