Aircraft EASY X4 Sequence controller 2506018

£2,042.05 inc VAT £1,701.71 ex VAT

Description

Aircraft EASY X4

Many compressed air stations consist of several compressors: EasyX4 is a weekly programmable controller that allows up to four compressors to be configured based on actual air requirements.

EasyX4 is the simplest solution for compressor operation and monitoring of complex compressor systems with up to four compressors – at constant speed.

Programming is intuitive. It is sufficient to set the four pressure ranges (if four is the number of connected units) and then to define at which time the entire compressor station should be turned on and off, with which pressure each compressor has to work.

Three programming levels:

- MANUAL: The compressors are set to a preset operating pressure range

- AUTOMATIC: Pressure ranges are exchanged after a programmable time interval

- GROUP PROGRAMMING: Compressors can be switched within groups

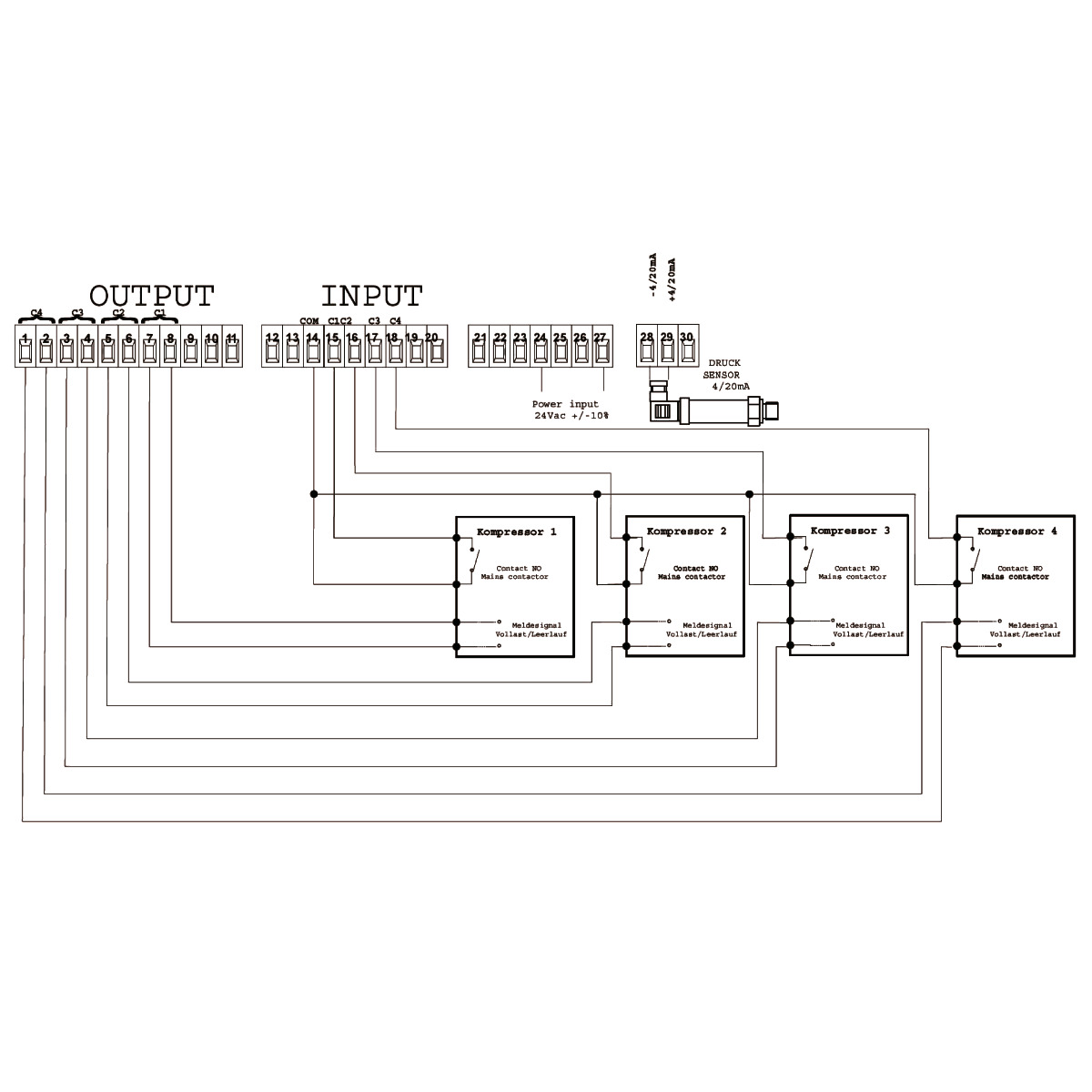

Function Description:

Once the EASY X4 Sequence Controller is powered up, the system powers up and establishes the operating conditions that existed at the time of shutdown: “Standby” or “Active”. In “stand-by” mode, the compressors are not enabled for operation, and only this mode allows access to the menus by pressing the [OK] key.

In contrast, in the “active” mode of operation, the EASY X4 Sequence Controller releases the compressors according to the modes and times specified by the active program, based on the pressure present in the system and sensed by the pressure transducer.

In “stand-by” mode, pressing the Start (I) key places the EASY X4 sequence controller in the status initialization state.

If the system pressure falls below the value entered in parameter [MinPrint], the value set by [Weight. Compr:] certain compressor is activated for a period corresponding to the parameter [Fill time:] (these parameters can be accessed via the menu [Settings], see section “Setting the functions”). This allows the system to be filled when it is empty (a typical example is to switch it on every morning), using a single compressor and avoiding the switching on of all machines connected to the EASY X4 sequence controller.

After the fill time, the EASY X4 sequence controller executes the programs entered by the operator according to the pressure and the program active at that time and day.

All information about the status of the machines is displayed on the main screen.

The possible states are: stand-by, under pressure, empty, disabled and in alarm. The description of the symbols that display these states can be found in the section “Main screen page”.

A fault occurs when the EASY X4 Sequence Controller does not receive feedback on the status of the remote commander of the active compressor (for more information on the type of message, see the “Installation” section), within the parameters set by the [Time Back:] parameter. reached in the [Settings.] menu.

In order to avoid the simultaneous start-up of several compressors, the parameter [Start delay:] can be used to set the activation of two consecutive compressors with an intermediate time delay. In this way electrical overloads can be avoided. The sequence controller EASY X4 can be brought into “stand-by” status at any time by pressing the Stop (O) key. All compressors now go into idle mode and stop after the idle time set on the individual machine or on the local controller. To read or change this value, see the documentation of the compressor manufacturer.

When the control unit is not supplied, the control contacts of the compressors remain closed, that is, the compressors are enabled for operation. This represents an emergency function which ensures the operation of the compressors even if the sequence controller EASY X4 is not supplied due to external causes (interruption of the power supply, etc.). The compressors are thus operated in accordance with the pressure specifications given directly by each individual controller or pressure monitor. To read or change these values, see the documentation of the compressors.

The operating pressure ranges that are set directly on the individual controllers or pressure switches of the compressors must exceed the pressure ranges set on the EASY X4 sequence controller. This excludes overlays in the operating logic of the EASY X4 sequence controller.

In addition, this ensures “emergency operation” of the compressor in the event of a fault in the EASY X4 sequence controller. For example, if pressure ranges between 8.8 bar and 9.7 bar are set on the EASY X4 sequence controller, the minimum pressure values set on the controllers or pressure switches of the compressors must fall below 8.7 bar and the maximum values must exceed 9.8 bar. In any case, however, the pressure loss between the pressure prevailing at the installation position of the converter of the sequence controller EASY X 4 and that measured by the converters of the compressors must be taken into account.

Example: If a pressure drop of 0.4 bar is measured between the mounting position of the converter of the sequence controller EASY X4 and the compressors while the system is running (without compressed air flow, the pressure loss is zero), taking the above example into account, the compressors would have to be used with a 0.4 bar higher pressure. Therefore, the maximum operating pressure of the compressors should be set to a value that exceeds 10.2 bar (9.8 + 0.4). This pressure could exceed the maximum operating pressure of the compressors themselves.

Dimensions(mm):

L: H: W:

Weight: 8.4kg