Optimum OPTIturn TH 8030D Centre and spindle lathe Heavy Duty Manual Metalworking Lathe

£45,797.48 inc VAT £38,164.57 ex VAT

Features:

- Hardened and ground Z-axis guideway

- Spindle mount Camlock DIN ISO 702-2 No. 8

- Precisely crafted sled

- All guides can be adjusted by wedge strips

- Adjustment range upper slide ± 90 °

- Guaranteed concentricity of the spindle nose better than 0.015 mm Waves, wheels and main spindle running in oil bath

- Gear wheels smooth, hardened and ground with 2 adjustable precision tapered roller bearings

- Clear selection lever for switching the feed rates

- Closed design of the rapid-action feed gear

- Gears and shafts hardened and ground in an oil bath in precision bearings

- Handwheels decoupled and tested according to EN 23125

- Two-channel right-left switch tested to EN 23125

- Switch with life cycle calculation, tested according to EN ISO 13849

- Right / left rotation on bed carriage via switching spindle switchable

- Central lubrication in the bed slide

- Coolant device with separate coolant tank with level indicator and oil separator; easy and complete emptying and cleaning according to DIN

- leading spindle

- Emergency stop blow switch, motor protection switch, lockable main switch

- Emergency stop device with foot control

- Safety handwheels with release function in the X-axis

- Handwheels with adjustable fine scale 0.04 / 0.02 mm

- Tailstock for taper turning ± 10 mm adjustable

- Tailstock quill and handwheel with adjustable fine scaling

- Tailstock crank for position change

- Tailstock quill with two adjustable ratios 1/4 or 1/1 turn

- LED machine lamp

- Fast feed – pushbutton and selector lever for activating the rapid traverse for plan and longitudinal direction for even more efficient work. Does not switch off the entire machine when retracting into the limit switch

- Safety limit switch with positive opening contacts

- Electric engine brake with fast emergency stop – in normal operation fast stop without caster

- Electrics with Siemens components

- Energy chain for gentle line and hose routing

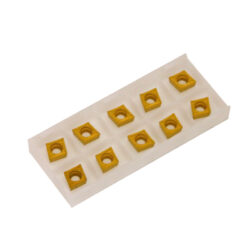

- Quick change steel holder SWH 9-D

- 1 steel holder 41 x 180 type D for square chisel 32 mm

Digital position indicator DPA 21

- Significant reduction in production

- glass scales

Included as Standard

- 315mm 3 Jaw Chuck

- 400mm 4 Jaw Chuck

- 480mm Face Plate

- 20 – 190 mm Fixed Steady

- 20 – 130 mm Travelling Steady

- Coolant System

- Rear Splash Guard

- Toolpost Chip Guard

- Spindle Footbrake

- 2 Axis DRO

- Electrically Interlocked Chip Guard

- Cross & Longitudinal Power Feed

- Machine Lamp

Description

0346-2240

Optimum OPTIturn TH 8030D Centre and spindle lathe Heavy Duty Manual Lathe

Leading and traction spindle lathes, which are characterized by high flexibility, precision and cost-effectiveness. With digital position indicator DPA 21 and quick-change steel holder

Technical Data

|

Dimensions and weights

|

|||

| Length (product) approx. | 5287mm | Net weight approx. | 3820kg |

| Width/depth (product) approx. | 1525mm | Load bearing capacity | 1,4t |

| Height (product) approx. | 1925mm | ||

| Work areas | |||

| Max. height | 400mm | Swing diameter above planing slide | 570mm |

| Max. width | 3050mm | Turning length in bed bridge | 250mm |

| Swing diameter above machine bed | 800mm | Bed width | 400mm |

| Swing diameter in bed bridge | 1035mm | ||

| Speed range | |||

| Number of gears | 16 | Speed range |

25 – 1600min¯¹

|

|

Fast motion speed

|

|||

| Rapid motion speed | 3800mm/min | Explanations about rapid motion |

max. 5 min (30 min. break)

|

| Electric Data | |||

| Drive motor output | 11kW | Mains frequency | 50Hz |

| Supply voltage | 400V | ||

|

Cooling lubricant system

|

|||

| Cooling lubricant system coolant pump output | 150W | ||

| Spindle | |||

| Spindle chuck | Camlock DIN ISO 702-2 No. 8 | Spindle bore/rod passage diameter | 105mm |

| Spindle cone | MT 7 | Tool holder max. chuck height | 32mm |

| Tailstock | |||

| Tailstock chuck | MT 5 | Tailstock quill stroke | 235mm |

| Pitches | |||

| Metric pitch | 0.45 – 120mm/rev | Diametrical pitch | 7/8 – 160 |

| Number of metric pitches | 54 | Number of diametrical pitches | 42 |

| Imperial pitch | 80 – 7/16Threads/1″ | Modular thread pitch |

0.25 – 60mm/rev

|

| Number of imperial pitches | 60 | Number of modular thread pitches | 46 |

| Travel | |||

| Travel X axis | 230mm | Travel Z axis | 368mm |

| Feed | |||

| Longitudinal feed range | 0.044 – 1.48mm/rev | Flat feed range |

0.022 – 0.74mm/rev

|

| Number of longitudinal feeds | 25 | Number of flat feeds | 25 |

|

Electrical connections

|

|||

| Total rated value | 12kW |

Additional information

| Weight | 3820 kg |

|---|---|

| Brand | OPTIturn |

Reviews

There are no reviews yet.